Sheet metal forming is a widely used manufacturing technology that uses sheet metal to create various components and assemblies. This process involves a variety of forming techniques, each of which plays a unique role in specific applications. Here is an overview of sheet metal forming, explaining its basic principles and some common forming techniques.

Q1: What is sheet metal forming?

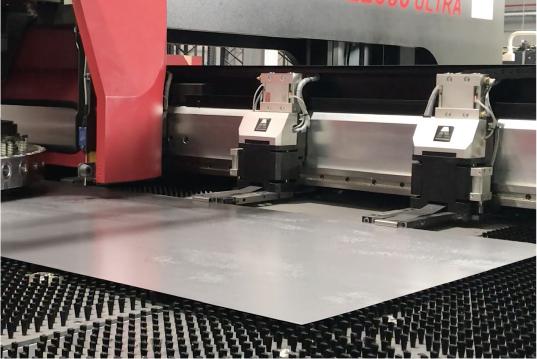

A: Sheet metal forming is a manufacturing process that transforms sheet metal into various components and finished products. It typically involves steps such as cutting, bending and stamping to create the desired shapes and structures. Machan uses advanced sheet metal technology, automated processes and state-of-the-art machinery to provide customers with high-precision, efficient production solutions that ensure product quality and consistency.

Q2: What are the applications of sheet metal fabrication?

A: Sheet metal fabrication is widely used in industries such as automotive, electronics, telecommunications, construction and more. Machan offers customised sheet metal solutions for various applications, including automotive toolboxes, medical carts, energy storage devices and more, to meet diverse customer needs.

Q3:How does the sheet metal manufacturing process work?

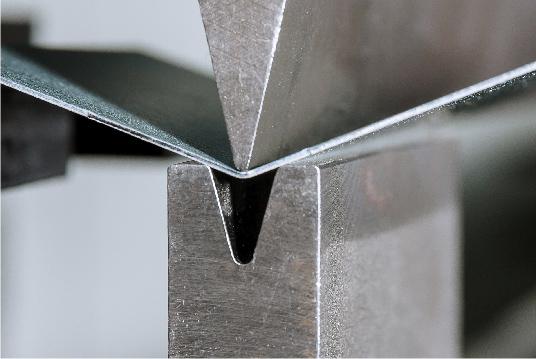

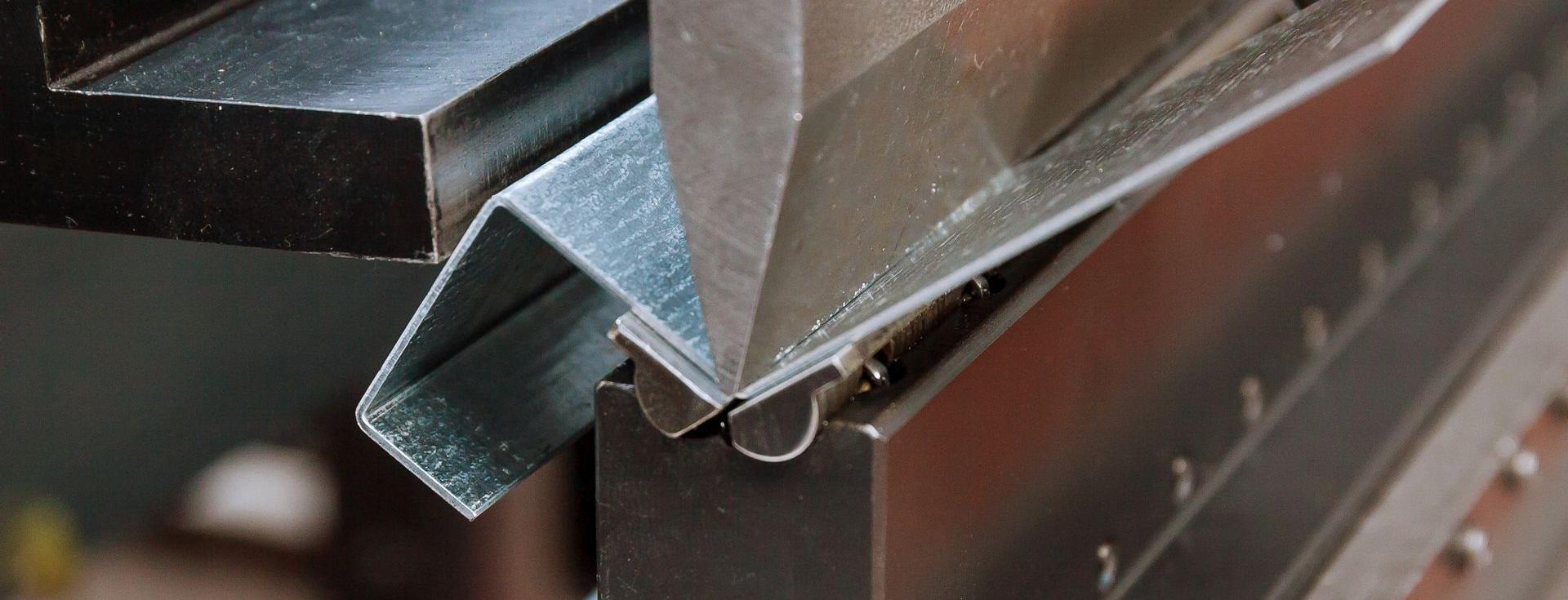

A: The sheet metal manufacturing process starts with cutting the sheet metal, followed by bending or stamping to achieve the desired shape. Machan uses advanced laser cutting technology and automated press brake equipment to ensure high precision and efficiency, providing highly customised and standard-compliant products.

These steps form a complete sheet metal manufacturing process, each of which ensures the quality, precision and efficiency of the final product. In software development, Machan has achieved virtual integration, including AI, automatic parameter setting and integration with intelligent machines.

Q4: Main types of Sheet Metal?

A: Sheet metal mainly includes steel, aluminium alloys and copper. Machan offers a variety of material choices, including steel, stainless steel and aluminium, based on customer requirements and product applications. This differentiation allows us to meet the performance requirements of various industries.

Q5: Industries where Sheet Metal working is widely used?

A: Sheet metal fabrication is widely used in industries such as automotive, electronics, aerospace, energy and construction. With over 98% of products sold to global customers, including industries such as automotive, medical, hand tools, education and logistics, Machan provides professional sheet metal solutions to meet the precision and reliability requirements of various industries.

Q6: What are the benefits of metal fabrication?

A: Metal fabrication offers high strength, durability and design flexibility. Machan is committed to delivering high quality metal products, ensuring customers receive durable and compliant products through the use of modern processes and materials. The benefits of metal manufacturing also include recyclability, which contributes to environmental protection and sustainable development.